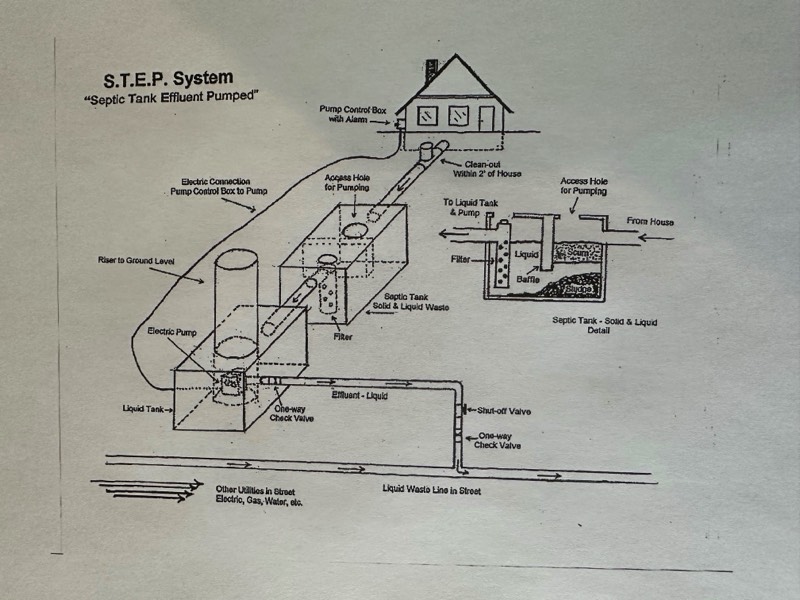

The picture above represents a typical STEP system in our community. The green tops/lids are riser covers used to seal the openings in the two separate 1000-gallon vaults located below ground. Risers are 24 or 36 inch diameter vertical pipes are inserted into or butted on top of the access holes in your vaults. These are required for inspection, problem resolution and specific system maintenance. Risers are sealed to prevent inflow. Riser tops are generally held in place by self-tapping screws that can be removed for vault inspection/access. In this section we will discuss what is under each of the riser covers and what maintenance should be performed on each.

___________________________________________________________________________________________________________________________________________________________________________________

SOLIDS VAULT

The first vault, the Solids Vault, has no specific picture provided here since there is no Homeowner performed maintenance required. This vault looks virtually the same as the Liquids Vault without any filter system as shown below. Waste comes from your home and enters the Solids Vault. Most solids settle to the bottom and some will rise to the top as a normal part of digestion/decomposition. This top solids layer is kept in the Solids Vault by a baffle. The liquids are therefore in the middle of the tank (if it were divided into sections) and flow from the Solids Vault to the Liquids Vault through a 4 inch pipe. Solids build up over time and they must be pumped by a Service Provider just like a typical on premise/on-site septic system. Depending on the number of people in your household, your garbage disposal and hygiene product flushing practices, a pumping service, (See Service Provider Section), should be called every 3 to 5 to years. Failure to maintain the solids vault can cause system blockage, which could create a backup in your home. It is uncommon that the system would get to a blockage point before you become aware but, as with a typical septic system, this can occur.

___________________________________________________________________________________________________________________________________________________________________________________

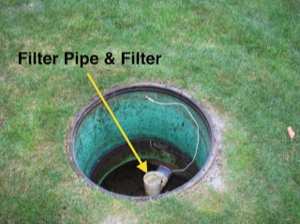

LIQUIDS VAULT

___________________________________________________________________________________________________________________________________________________________________________________

PUMP VAULT

CHECK for additional circuit breakers within your controller box that may have tripped. If you've checked all the power sources and everything is in working order, then quiet the alarm. Depending on your alarm installation, you may have a box with a red button on the outside of your house or you may have an alarm with a toggle switch inside your garage. Pushing the red button or moving the toggle switch to silent will silence the alarm. Don’t ignore the alarm. You should wait before silencing the alarm to make sure the pump isn’t working to catch up. If you push the button and silence the alarm that’s all you’ve done, silenced the alarm. The problem is still there. Should your alarm sound during non-business hours, you can continue to use water in your home but it should be on a very limited basis. Knowing this allows you to make an immediate service call but request morning service during normal business hours. Your specific situation will dictate your action here. Note on community-wide maintenance issues: Also there have been instances where an issue with the main sewer line can cause individual alarms to trip. Contact a Board member to see if there is a system wide problem that could be affecting you. Also power outages can last for several days. It is common during an outage for most to continue to use water on a limited basis. This can cause many vaults to fill beyond routine capacity. As soon as the power is restored, many system alarms may sound throughout the neighborhood. This is normal. When power goes out, our pumps stop, but liquid flow, if you continue to use the system, will not. It’s important to note that our STEP mainline is not sized for the volume of pumping that occurs in this situation. Because of this, it could take hours for your system to pump down the liquids to a level that resets the alarm. In these situations, we suggest continued careful use of water during and immediately following power outages and if the alarm continues for a lengthy period of time, you might want to shut off your pump, to prevent constant running. Turn it back on in a few hours to let the overall system catch up. This will help mitigate the system capacity issues.

Once a riser/tank inspection has been completed, clean the riser rim and the lid gasket of any dirt etc., put the riser lid back in place and tighten the self-tapping screws snuggly, but not so tight as to cause the lid to deflect, break or strip the screw holes. If the screws do strip or the holes have worn out from repeated removal, remove them all and rotate the lid to a fresh area (where the old holes in the riser rim cannot be seen and reattach (relying on the self-tapping feature of the screws). It is important that no surface water enters this vault or any of the vaults.

___________________________________________________________________________________________________________________________________________________________________________________

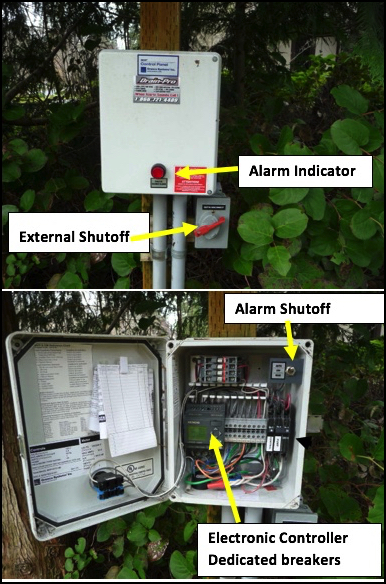

CONTROLLER BOX

Directly below are pictures of your STEP System Control Box and Pump Shut-off switch which should be located near your risers. Generally this box is mounted on the side of the house or on a freestanding post near the tank lids. This box and associated pieces generally have a pump on/off switch, the alarm shutoff, the pump control module and individual circuit breakers. Some of the units are capable of tracking pump cycles and retaining information about pump operations. If you do not have any documentation for your control box, you might want to search the web. The controllers are essentially small computers and if they fail, they may or may not be repairable. The pictures show one installation in our neighborhood. Yours will likely be similar.